The new year is a good time to re-examine various approaches to business and determine what methods or processes can be changed to bring about better results. One specific area, as it relates to facility expansion or new construction, is worth serious evaluation. It offers the potential to completely transform conventional construction realities and deliver increased advantages that can be seen almost immediately.

This game changer isn’t new. However, it’s becoming more widely accepted because of its proven speed and cost-efficiency results. It’s the application of lean construction techniques utilizing systems construction and a design-build process.

Old habits and familiar ways of doing things die hard. On the other hand, new thinking and objectivity often lead to previously unforeseen rewards. One perfect example is found in the contrasting mindsets that accompany conventional construction methods versus lean construction practices.

In the former, the project owner, architect and contractor are often involved in on-going, give-and-take discussions in an effort to manage value throughout the design and build process.

In the latter, defined goals, clearexpectations and project value are accounted for in the pre-construction phase. So, there’s up-front agreement on exactly what you’re going to get and how it will be achieved. And that’s just the beginning!

8 Indisputable Benefits of Lean Construction:

- Value engineering from project initiation

- Improved project owner/construction team communication

- More efficient planning and control systems

- Greater project accountability and predictability

- More timely materials delivery & site staging

- Improved worker productivity and safety

- Reduced costs & elimination of waste (time, materials & labor)

- Radically reduced construction completion schedules

A Process of Coordination and Collaboration

Lean techniques accelerate the construction process, but they’re far from rushed or hasty. On the contrary, they involve deliberate, regimented steps performed in a well-orchestrated sequence. Getting work to flow reliably and consistently on the job site – with the fewest possible interruptions – is dependent upon Integrated Project Delivery (IPD), which emphasizes a culture of collaboration, perfect alignment of the supply chain, engineered building systems, and elimination of waste.

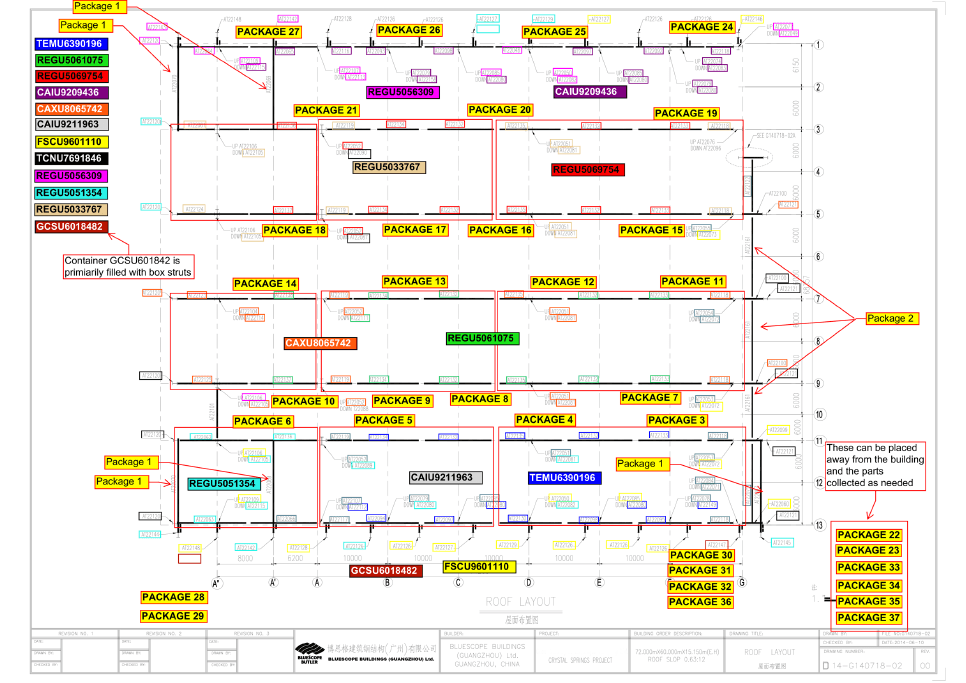

The process of coordination begins early as the owner, GC and erector work together to determine the construction sequence. The sequence then establishes the building systems fabrication timeframe and just-in-time materials delivery to the job site. A synchronized system for materials loading, delivery and unloading simplifies shake-out; reduces loss of materials; enhances construction efficiency; and minimizes the need/cost of short-term storage. This entire process helps to error-proof the worksite.

Without such coordination, materials are shipped in random sequence to fill an order. So, when they arrive at the site, construction crews are unsure what container is needed where, potentially leaving materials to sit for weeks, become misplaced, or damaged. All which confuse site crews and compound material and labor costs.

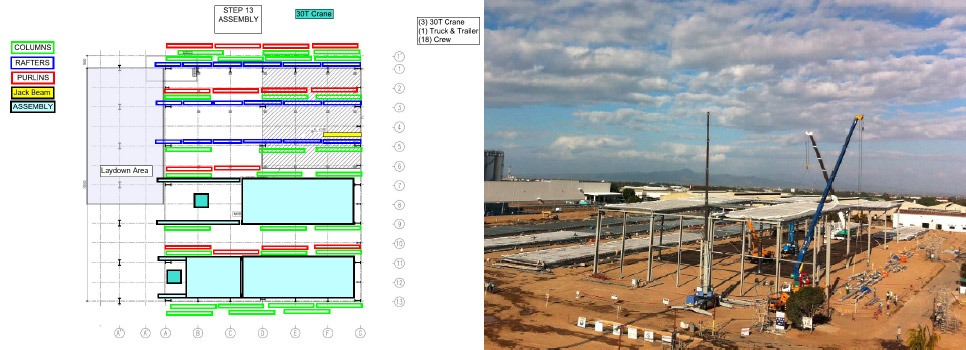

In Lean Construction, a staging Step Chart is used to establish a precise workflow, which enables synchronized, phased completion.

A Site Map shows which containers are needed for the various column lines, referencing items identified in the Step Chart.

Lean Construction Is Not Lean on Advantages

Since much of the labor is performed off-site with systems construction, less on-site labor is required. This is a huge advantage given the global shortage of skilled or properly trained labor. In addition, Butler structural systems feature bolted assemblies with factory-punched wall and roof panels for accurate, weathertight assembly. Therefore, installation requires less labor; ensures greater installation quality; and condenses erection timeframes.

This approach is not only more nimble; it also prevents the under-utilization of resources, and assures better risk management, predictable finished quality, and buildings completed in at least a third less time than conventional construction, which reduces overall costs.

Finally, since the entire process is grounded in continuous communication and reporting, there are few, if any, surprises. Also, progress assessments are made throughout the construction process to impact continuous improvement.

Lean construction may not be right for every project, but isn’t it worth further investigation?